The quotation of insulated glass

Sado Germany Window JSC sincerely thanks for your interest in our products. We would like to submit a standard quotation as follow:

Note:

– The above price does not include 10% VAT and shipping charges.

– Unit price does not include packaging costs.

– This quotation applies to the rectangle of material consumption rate of 20%. The official quotation will be prepared by the company’s Price Department based on the detailed design of your door. Quotes are valid within 15 days.

– The exchange rate following Vietcombank on 30/12/2019: 1 USD = 23230 VND

Detailed description of insulated glass

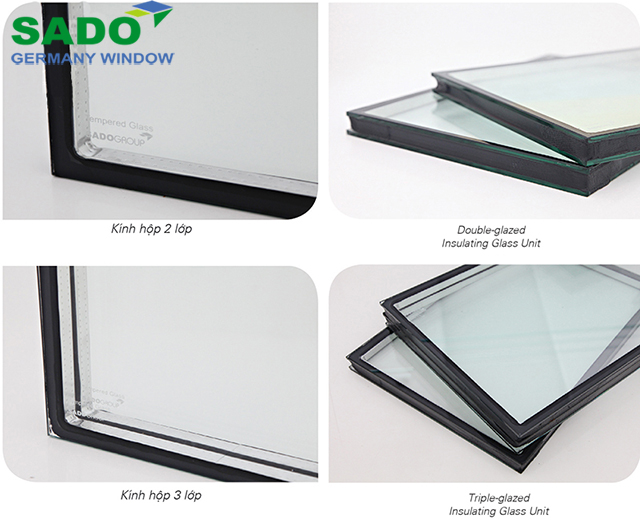

What is insulated glass?

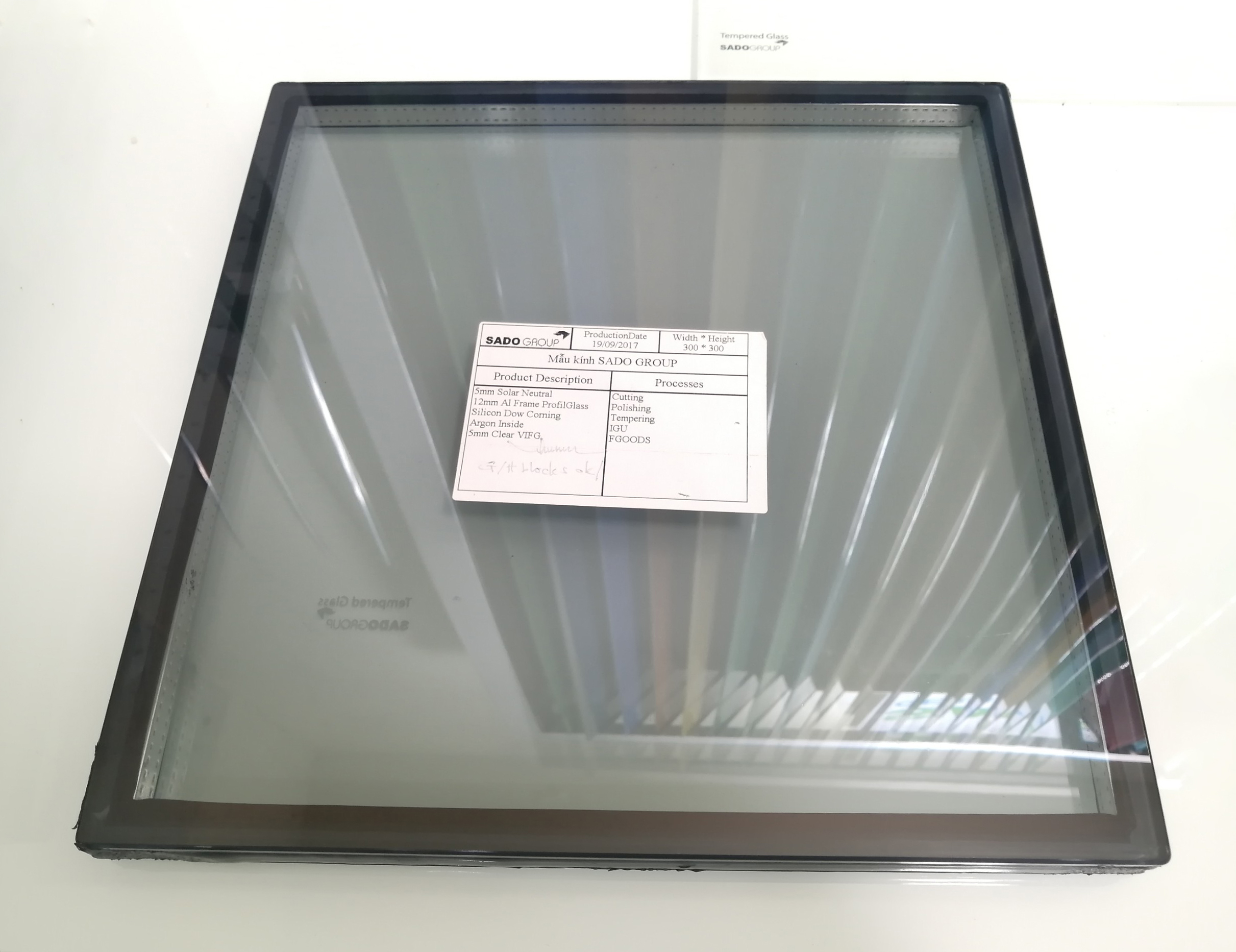

Insulating glass/ double glazing consists of two or more layers of glass separated by an aluminum spacer filled with desiccants inside. The egdes are sealed to create a dead air space between the layers. The insulated glass of SADO offers higher thermal and sound insulation because it is filled with the hig purity argon gas.

Insulated glass are manufactured on the advanced technology lines of LiSEC GROUP. Attached accessories included secondary seal, butyl, polysulfide, silicone and aluminum rods, all meet European quality standards.

VIFG insulated glass= VIFG tempered glass + space, Silicon, argon gas + VIFG tempered glass

(VIFG is the number one float glass brand in Vietnam)

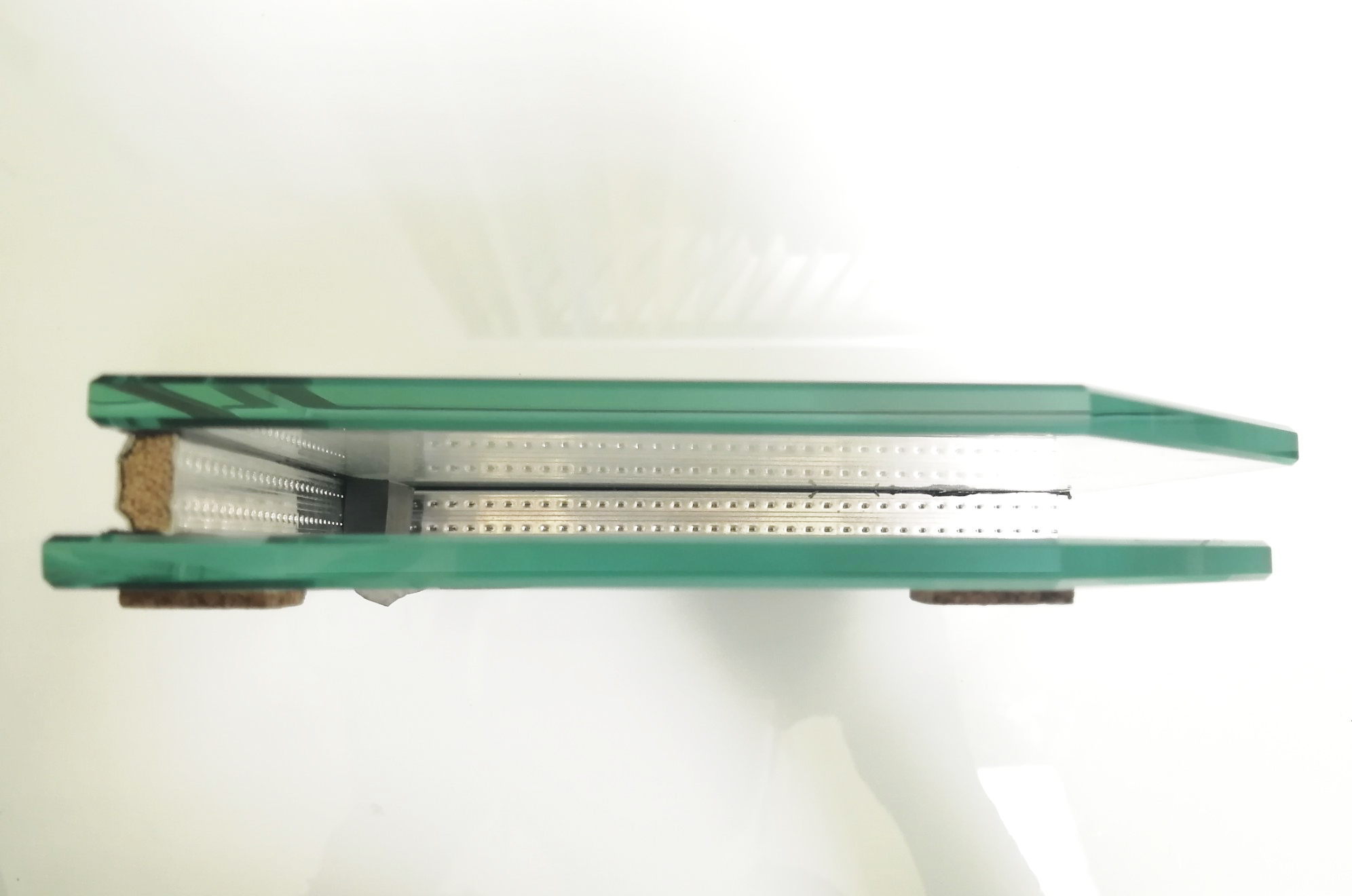

Component of insulated glass

Glass: tempered glass is processed from float glass of VIFG. The glass has strong impact resistance and good heat resistance, tempered glass is 4-5 times stronger than normal glass. Especially, when there is too much impact, the glass will shatter into fragments like pomegranate seeds, difficult to damage.

Desiccant: Helps maintain inert-gas pumped between the two layers of glass always in a dry state, preventing heat transfer inside and outside.

Spacer: between the glass layers, spacer sizes from 5mm, 6mm, 9mm, 12mm, 24mm

Air space: is filled with Japanese argon gas to increase the ability of sound and heat insulation.

Silicone Dow corning: (made in USA) helps isolate the inside gas from the outside air.

Outstanding feature of insulated glass

Excellent sound and thermal insulation: insulated glass is filled with inert-gas in the middle of two glass layers for effective sound insulation, minimizing sound pollution. Besides, inert-gas also helps insulating glass to prevent heat transfer between the internal and outside environment, helping your space stay cool in the summer and warm in the winter.

Against dew condensation: Condensation can occur in insulated glass when there is a large temperature difference from inside to outside. This interferes with your vision or can cause mold to affect indoor air quality. The structure of the insulated glass helps to control dew condensation.

Safety: insulated glass is assembled from 2 layers of tempered glass together so the safety of the glass is significantly increased.

Economic efficiency: Thanks to effective sound and heat insulation ability and ensure high light transmission ability to significantly reduce the need to use air conditioning, energy consumption of lamps, …

Application

Insulated glass is the optimal choice for all architectural and construction projects, especially projects requires strict control of temperature and noise such as:

+ Buildings near highways and railways;

+ Office buildings, hotels, hospitals;

+ Waiting rooms, air traffic control stations at airports;

+ Recording studios of radio and television stations.

Specification of insulated glass:

| Thickness (thickness of glass sheet+frame+glass sheet) | 12 – 60mm |

| Standard thickness of space | 6mm, 9mm, 12mm, 15mm, 19mm, 24mm |

| Maximal glass size | 2900 x 5200 mm |

| Minimal glass size | 180 x 350 mm |

| SADO can produce the following types of insulated glass | |

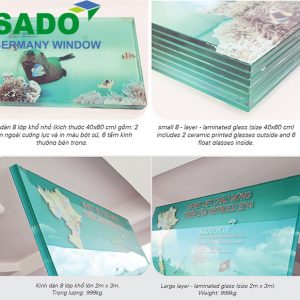

| Insulated glass – 2 or 3 layers from the following types of glasses: float glass, tempered glass, ceramic printed glass, laminated glass, low-e glass, reflective glass. | |

| Stepped insulated glass – 2 or 3 layers (the glass panels have different sizes) for special request constructions. | |

The insulated glass line

The insulated glass line of SADO is one of the most modern productions line provided by LISEC corporation. This is a perfect line for manufacturing high quality double ad triple glazings and special insulating glass units with up to 3 steps and gas-filled units (stepped units). SADO also uses one or more tempered or laminated glass sheets for superior insulating glass. Moreover, the advanced insulating line enables to use special materials to manufacture fire-resistant glass.

The line consists of following componentsh

The automatic and manual bending machines

The automatic and manual desiccant filling

The butyl coating machine

The fully automated washing and drying system

the pressing and gas-filling machines

The automated and manual sealing system for applying silicone, polysulfide to glass

The system of cranes for loading glass maintain the originally geometric structure of the glass and avoid glass deflecting by the relative movement between the glass sheets.

Outstanding

– The glass sheets are mechanically washed by distilled water treated by eurowater’s system. As a result, the glass reaches the highest standards of cleanness and transparency.

– The gas-filling machine can carry out an unrivaled gas-filling rate up to 95%, hence minimizing gas losses;

– Fully automated silicone and polysulfide sealing machines ensure the exact calculation of material volume;

– The high quality materials for processing insulating glass such as silicone, polysulfide, butyl, profile bars and desiccants were imported from the USA and European countries. They are suitable for different weather conditions; therefore, the insulated glass always maintain higher thermal insulation, sound reduction and long-term durability.

| Độ dày kính | 16mm, 18mm, 19mm, 21mm, 22mm, 24mm |

|---|

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.